HOT INDUCTION BENDS MANUFACTURER IN INDIA

Multi Metals (India) offers a different range of hot induction bend in carbon steel, alloy steel, stainless steel, low and high-temperature steel pipes for Power, Oil & Gas, Construction, Chemical Industries. We supply precision manufacturing and narrow dimensional tolerances in wall thickness reduction, ovality, bending radius, and angles. We can bend both seamless and welded pipes between the range of 3D-10D bending radius.

We will be glad to quote your inquiries for induction bent API5L Gr: B, X42, X46, X52, X60, X65, and also European norm pipes. Hot bending of pipes (above 750°C) protects the mechanical properties of the material and post bending heat treatment like normalizing, stress relief heat treatment is also available at our facilities.

In final inspection, we do dimensional and visual controls, hydro test, 100% NDT on welds to provide minimum tolerances on bends.

Table of Contents :-

ASME B16.49 Induction Bends Specification :-

ASME B16.49 is the standard specification covering the design, material, manufacturing, testing, marking, and inspection requirements for factory-made pipeline bends of carbon steel materials that have controlled chemistry and mechanical properties, produced by the induction bending process, with or without tangents. This Standard covers induction bends for transportation and distribution piping applications such as ASME B31.4 and ASME B31.8. Process and power piping have differing requirements and materials that may not be appropriate for the restrictions and examinations described herein and, therefore, are not included in this standard.

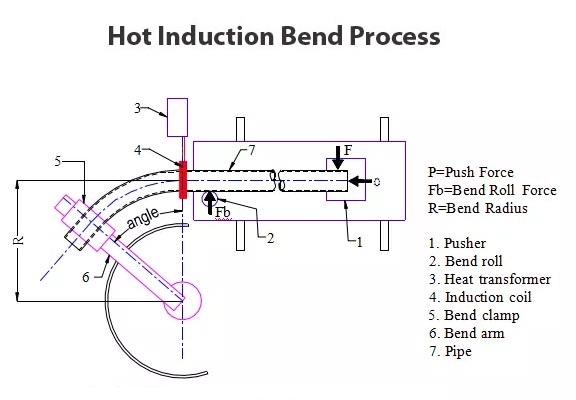

Induction Bends Manufacturing Process :-

Induction bends manufactured to ASME B16.49 can be either made from seamless or welded pipes with or without tangent length by cold- or heat-forming process. Generally, heat-forming process is applied which utilizes the mid-frequency induction-bending machine. This process utilizes induction heating to heat a narrow band 360 deg around a pipe or cylinder at the point of bending as the pipe or cylinder is being pushed through the inductor coil at a constant velocity. After the material passes through the coil, it may be cooled by forced air or water spray, or it may be allowed to cool in still air. Bends in any producible wall thickness and diameter are covered.

Mid-frequency induction-bending machine for the manufacture of induction bends.

ASME B16.9 Hot Induction Bends Supply Range :-

|

Dimensions |

ASME/ANSI

B16.9, ASME B16.28, MSS-SP-43 |

|

Size |

2"NB

TO 48" NB |

|

Thickness

/ Schedule |

Schedule

5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120,

S140, S160, XS, XXS etc. |

|

Type |

Seamless

/ ERW / Welded / LSAW / Helical / Fabricated |

|

Bend

Radii |

75

/ 100 / 150 / 250 / 300 / 500 / 800 / 1,000 / 1,200 / 1,500 mm |

|

Bending

Radius(R) |

R=1D,

2D, 3D, 5D, 6D, 8D, 10D or Custom |

|

Bending

angle (θ) |

15°,

30°, 45°, 60°, 90°, 135°, 180° |

|

Mill

specification |

MESC

SPE 74/002 2018, MESC SPE 76/200 2018, EN 10204 -3.1, ISO 10474 -3.1 |

|

Testing

Facility |

Radiography

(X-Ray, Gamma-Ray) / UT, MT, LPI, MP / Hardness |

ASME B16.9 Hot Induction Materials & Grades :-

|

Black

Steel Induction Bend |

P235GH,

P235TR1, P235TR2, P265GH, P355N, P195GH, 16Mo3, L360NB, L360MB |

|

API

5L Induction Bend |

API

5L - Gr.B / X42 / X46 / X52 / X60 / X70 / X80 / X100 / X120 (PSL1 & PSL2) |

|

ISO

3183- L245 / L290 / L320 / L360 / L415 / L485 (PSL1) |

|

|

ISO

3183- L245N / L245R / L290Q / L360Q / L415Q / L485Q (PSL2) |

|

|

High

Strength Carbon Steel Induction Bend |

ASTM/

ASME SA 860 WPHY 42, WPHY 46, WPHY 52, WPHY 60, WPHY 65, WPHY 70 |

|

Low

Temp Carbon Steel Induction Bend |

ASTM

A420 WPL3, A420 WPL6 |

|

Carbon

Steel Induction Bend |

ASTM/

ASME A/SA 234 WPB |

|

Low

Alloy Steel Induction Bend |

ASTM/

ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

|

Stainless

Steel Induction Bend |

ASTM/ASME

A/SA 403 WP 304/304L, 316/316L, 304H, 316H, 309, 310S, 317L, 321/321H,

347/347H, 904L |

|

Duplex

& Super Duplex Induction Bend |

ASTM/ASME

A/SA 815 WP S31803, WP S32205, WP S32750, WP S32760 |

|

Special

Grades Induction Bend |

Inconel,

Incoloy, Hastelloy, Monel, Titanium |

ASME B16.49 Hot Induction Bend Chemical Composition :-

|

Element |

Mass fraction, % based on heat and product analyses |

||||||||||||

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

V |

Nb |

CEQ |

|

|

|

Seamless and Welded Pipe |

|||||||||||||

|

Content |

≤0.30 |

≤0.50 |

≤1.60 |

≤0.025 |

≤0.015 |

≤1.00 |

≤0.30 |

≤0.25 |

≤0.50 |

≤0.10 |

≤0.10 |

≤0.43 |

|

ASME B16.49 Hot Induction Bend Mechanical Properties :-

|

Grade (Symbol) |

Yield Strength, min. |

Tensile Strength, min. |

Elongation, min. |

Hardness, max. |

Impact Test, Cv |

|||

|

ksi |

MPa |

ksi |

MPa |

% |

HBW |

HRC |

min. J |

|

|

P241 (X241) |

35 |

241 |

60 |

414 |

20 |

238 |

22 |

27 |

|

P290 (X290) |

42 |

290 |

60 |

414 |

20 |

238 |

22 |

27 |

|

P317 (X317) |

46 |

317 |

63 |

434 |

20 |

238 |

22 |

27 |

|

P359 (X359) |

52 |

359 |

66 |

455 |

20 |

238 |

22 |

27 |

|

P386 (X386) |

56 |

386 |

71 |

490 |

20 |

238 |

22 |

27 |

|

P414 (X414) |

60 |

414 |

75 |

517 |

20 |

238 |

22 |

54 |

|

P448 (X448) |

65 |

448 |

77 |

531 |

18 |

238 |

22 |

54 |

|

P483 (X483) |

70 |

483 |

82 |

565 |

16 |

247 |

24 |

54 |

|

P552 (X552) |

80 |

552 |

90 |

621 |

16 |

247 |

24 |

54 |

Hot Induction Bend Heat Treatment, Test & Inspections :-

Each induction bends shall be heat-treated after bending by one or more of the following methods :-

- Stress Relieve or Temper. Uniformly, heat between 480°C (900°F) and 675°C (1,250°F) and hold at temperature for at least 30 min per 25 mm (1 in.) of thickness at temperature, but no less than 30 min.

- Normalizing. Heat above the transformation temperature range and hold at temperature for a minimum of 20 min per 25 mm (1 in.) of thickness, but not less than 20 min, and allow to cool in still air.

- Quench and Temper. Heat above the transformation temperature range and hold at temperature for a minimum of 20 min per 25 mm (1 in.)of thickness and direct quench in either water, oil, or a synthetic quenchant. Reheat to temper as defined above. Quench facilities shall be of sufficient size and shall be equipped to ensure proper and uniform cooling.

According to ASME B16.49, the necessary test & inspection include: dimensional inspection, visual examination, tensile testing, charpy v-notch test, welding test, hardness test, ultrasonic test, radiographic test.

Hot Induction Bend Benefits :-

- Cost efficiency, straight material is less costly than standard components.

- They stronger than elbows with uniform wall thickness.

- Induction bending is a clean process. This doesn't needs any lubrication for the process nor water needed to cool down.

- Large radii for smooth flow of fluid.

- Less non-destructive testing of welds, such as X-ray examination will save cost.

- Induction bending reduces the no. of welds in a system.

- Pipes, Tubes and sections can be curved in multiple radii in one length

How to Order An Induction Bend :-

Induction bends may be furnished with an angle of 90°, 60°, 45°, or 30°, etc. The welding ends shall be prepared in accordance with ASME B16.25.

A commonly seen designation 3D, 5D, 6D, 7D, 8D, 9D, etc, denotes the length of its centerline radius. For example, 6″ 5D, the centerline R = 5 x 6″ = 30″ = 762.0 mm. To order an induction bend manufactured to ASME B16.49, some more details are required: seamless or welded, material, with or without tangent, quantity, heat treatment, e.g. 90° Hot-Induction Bend, ASTM A234 WPB, SM LS R=5D 8″ SCH40, with a tangent length=150 mm at each end, bevel end, QT.

Drawing of ASME B16.49 induction bend,

90° 3D with tangent lengths.